Home » Blog » 2023 » How to make a programable Led helmet in 10 steps – by ETERESHOP

A homemade programable LED light up helmet – why not? If you are well skilled in design, 3D printing, soldering, and programming, and have all the necessary components and tools, here is a brief photo guide to creating your own programmable light up helmet.

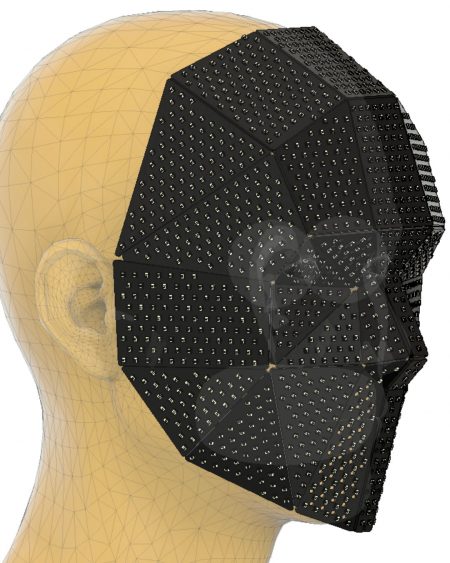

Our LED helmet design was based on a reference picture from our customer. Since we have already made helmets similar to this one, we used our previous designs – one for its back part and another one for the front part.

What you will need:

Our helmet consists of four 3D-printed parts – the back of the helmet, its front part that serves as a LED screen, and a couple of grilled covers for the ears.

For this model we used regular PLA plastic, the thickness of the layer is 0.29mm.

Before applying the undercoat, cut the holes for ears, ventilation, and wires, and clean the printed helmet parts from holders. As soon as you are done with this, start polishing the parts, and then applying the primer, and paint.

Tip – make sure to set a high quality of printing, otherwise it will be pretty hard to polish the parts.

Glue the ear covers to the helmet base. After that cover the whole helmet with a layer of lacquer, and glue an adjustable elastic ribbon and the inner EVA hat.

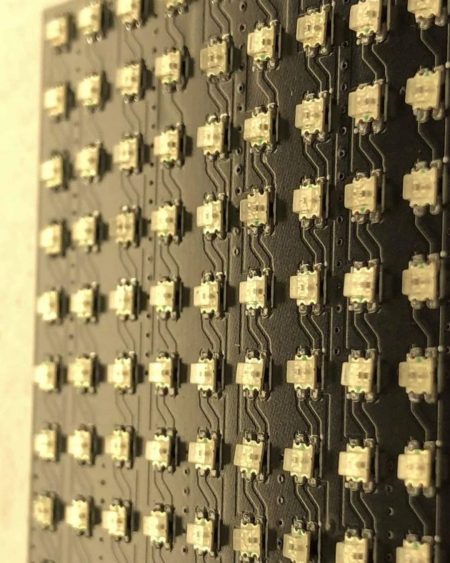

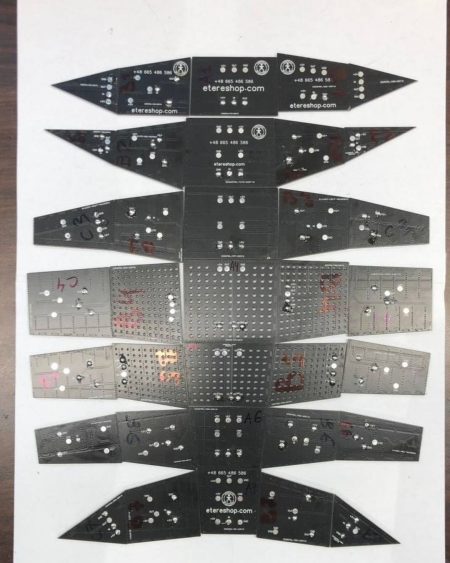

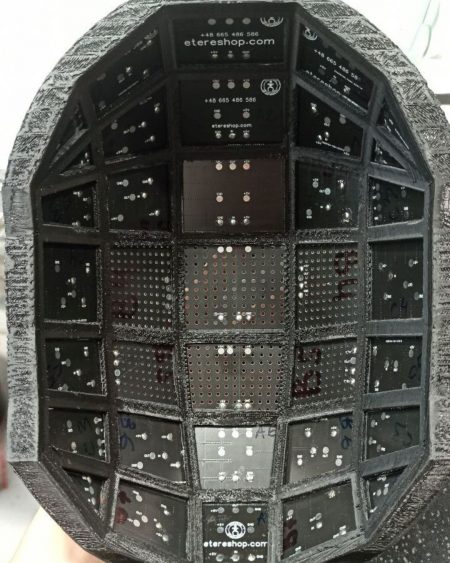

We used 35 base plates of different shapes and sizes, for which we prepared the same number of corresponding metal stencils.

First, put a metal stencil onto a base plate, so that all the holes fit precisely to each other, and fix everything with a masking tape. Then apply a soldering paste, lift the stencil, and put on the LEDs with a help of tongs according to the keys on the plates. For this light up helmet, we used approximately 3500 LEDs.

Now put the plate into a soldering furnace, set the temperature for 210 °C. Wait until it reaches the set temperature and hold for approx. 15sec, but not more – you can burn the LEDs.

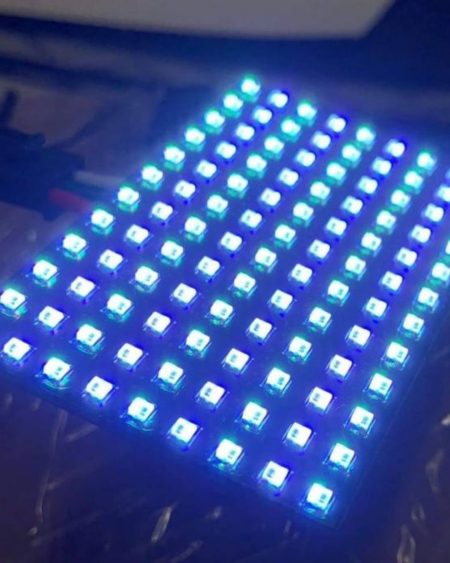

Take the plate from the furnace and turn it on to check if all the LEDs are glowing.

If some of the LEDs haven’t been soldered, you can do it with an iron.

Assemble the LED plates according to their numbers and attach them to the screen and one another with a help of a double-sided tape.

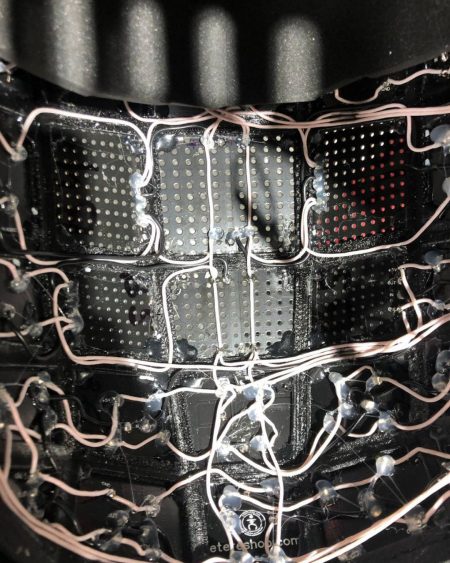

Now solder the common wire to the LED plates, and make connections to the controller, battery boxes, T-plugs, and the switch.

Usually we use Madrix software for creating light up effects. A high density of LEDs enables to display the effects in a high quality. Most of them were made so that 80% of the whole effect is in a black color. Due to this feature, we could show the volume of animated images. There were also effects with a full coverage like aquarium, but also scrolling texts, logos, names of the brands etc. All the effects were carefully selected to make use of the helmet’s possibilities to the full.

The control is carried out with a help of buttons connected to a long wire, so you can hide it inside the sleeve and hold the switch in your hand for convenience.

If you like the way we make our productst and interested in more programmable LED helmets and accessories by ETEREshop, tap here.

We are always striving to share valuable information with our audience, and we believe that our latest article is particularly important. We would be grateful if you could help us spread the word by sharing it with your friends and followers.